Apex Valves

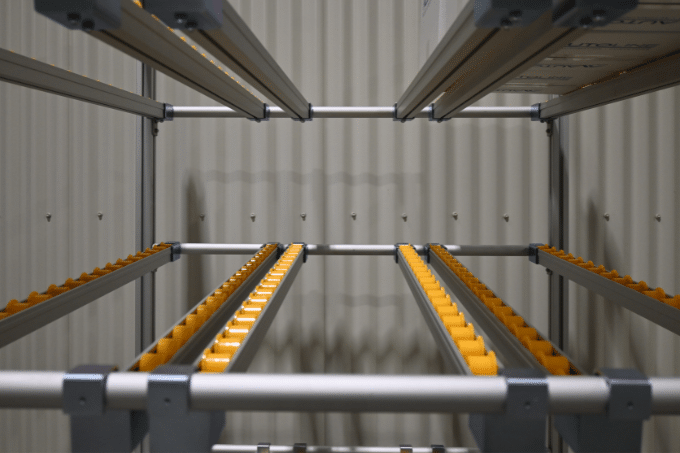

Designing Roller Racks for Efficient Workflow With SlotPro.

Background

Apex Valves is a New Zealand manufacturer specialising in high-performance plumbing valves for residential, commercial, and industrial applications. Based in Auckland, the company oversees product design, tooling, manufacturing, and assembly at its in-house facility, with a strong focus on quality and operational efficiency.

As part of a workspace upgrade, Apex Valves required a tailored solution to improve material handling within their assembly process. They needed a modular system to streamline movement, reduce manual handling, and create a more efficient flow of components across the factory floor.

SlotPro collaborated with the Apex team to design and build custom roller racks using the SlotPro aluminium extrusion system. Fabricated in-house and shipped fully assembled, the racks were ready for immediate use, helping to optimise workflow and support production efficiency.

Project Overview

Customer: Apex Valves

Purpose: Custom roller racks for material handling

Country: Auckland, New Zealand

Industry: Manufacturing Plumbing and Valve Components

Built Item: Roller racks

SlotPro Products Used: 40 x 40 SlotPro 4 Slot Standard Extrusion, 4 Series Universal Connector, 4 Series Transport and Base Plate 40 x 40, Tube Profile D28-1, Flat Suspended Glider Zinc, High Suspended Glider Zinc, Blue Rubber Castors, Flow Roller Track-B with Lip, T-Connector Plate.

The Solution

SlotPro and Apex Valves worked together to develop a set of custom roller racks designed to improve material handling on the production floor. The frames were built using 40 x 40 SlotPro aluminium profiles and Tube Profile D28-1, with all fabrication completed in-house at SlotPro prior to delivery.

Each rack incorporated Flow Roller Tracks to allow components to move smoothly between work areas. Wheels were added to the base to ensure easy movement and mobility, giving Apex Valves the flexibility to reposition the racks as workflows required.

To ensure durability and stability, the roller racks were reinforced with SlotPro connectors and transport plates. All assemblies were shipped fully built, ready for immediate use at the Apex Valves facility.

The modular extrusion design means the roller racks can be reconfigured or expanded in the future, giving Apex Valves flexibility to adapt the system as production needs change.

The Results

The completed roller racks provided Apex Valves with a practical and efficient system for handling components during assembly. Team members could transfer parts smoothly along the roller tracks, reducing manual lifting and keeping production moving.

Wheels on the base allowed each rack to be repositioned as needed, giving the team flexibility to adapt layouts and workflows without disruption. This mobility helped create a more responsive and organised production floor.

By delivering the racks fully assembled and ready to use, SlotPro reduced on-site setup and ensured Apex Valves could integrate the system immediately. The result was a cleaner, more streamlined process that supported faster assembly and improved efficiency.

The Impact

The new roller racks have quickly become an essential part of daily operations at Apex Valves. By improving material flow and reducing manual handling, SlotPro delivered a solution that supports both efficiency and convenience for the team.

Delivered fully assembled, the racks were easy for Apex to integrate into their workspace without delay. With minimal setup required, the upgrade was implemented smoothly and provided immediate benefits on the production floor.