Apex Valves

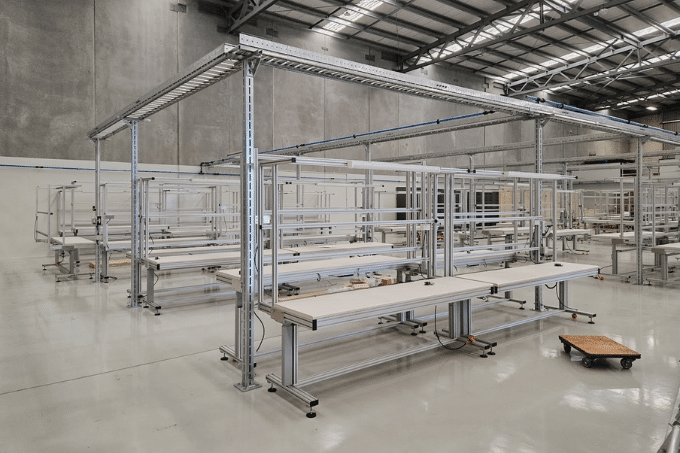

Creating Height-Adjustable Assembly Stations with SlotPro.

Background

Apex Valves is a New Zealand manufacturer specialising in high-performance plumbing valves for residential, commercial, and industrial applications. Based in Auckland, the company oversees product design, tooling, manufacturing, and assembly at its in-house facility, with a strong focus on quality and operational efficiency.

As part of a workspace upgrade, Apex Valves required a more ergonomic and modular solution for their assembly stations. They had developed a concept for height-adjustable workbenches tailored to their internal product assembly process and needed a partner to help turn that concept into a functional solution.

SlotPro collaborated with the Apex team to develop and build the workstation frames using 40 x 40 and 40 x 80 aluminium profiles. The frames were fabricated in-house at SlotPro and shipped fully assembled, ready for the addition of custom worktops and accessories.

Project Overview

Customer: Apex Valves

Purpose: Height-adjustable assembly stations for internal product assembly

Country: Auckland, New Zealand

Industry: Manufacturing Plumbing and Valve Components

Built Item: Height-adjustable assembly stations

SlotPro Products Used: 40 x 40 SlotPro 4 Slot Standard Extrusion, 40 x 80 SlotPro 6 Slot Standard Extrusion, 4 Series Universal Connector, 4 Series Transport and Base Plate 40 x 80, Articulated Foot M10 x 80, 4 Series Angle Bracket for 40mm Extrusion, 4 Series Cover Cap 40 x 40, 4 Series Cover Cap 40 x 80, 4 Series Roll-in Slot Nut with Spring M4, 4 Series Roll-in Slot Nut with Spring M5, 4 Series Roll-in Slot Nut with Spring M8.

The Solution

SlotPro and Apex Valves worked together to develop a customised assembly station tailored to Apex’s production needs. The frames were built using 40 x 40 and 40 x 80 SlotPro aluminium profiles, with all assembly completed in-house at SlotPro prior to delivery.

To provide adjustable working heights, SlotPro integrated a third-party lift system into the frame design. Each station featured a push-button control unit, allowing operators to raise or lower the bench as needed. All cables were routed neatly through the profile slots and concealed using cover profile to maintain a clean, professional appearance.

LED batten lights were mounted overhead using custom brackets. Power points were installed along the back of the benchtop area and wired directly into the frame. SlotPro handled all electrical installation and testing before delivery, ensuring the stations were ready to plug in and use immediately.

The completed frames were delivered fully assembled, with only the benchtops left for Apex to install. This approach reduced on-site work, maintained consistency across all stations, and provided a fully integrated solution that combined structure, lighting, power, and height adjustment in a single build.

The Results

The completed assembly stations provided Apex Valves with a functional, ergonomic, and professional workspace that supported their product assembly process. Operators could easily adjust the height of each station using the integrated controls, improving comfort and reducing strain during repetitive tasks.

Built-in LED lighting and power points meant the stations were fully equipped from day one. Workers no longer needed to run extension cords or move between work areas to access power. They were able to test products and operate tools directly at the bench, improving efficiency and streamlining the entire assembly process.

The consistent design across all stations created a clean and organised workshop layout. By reducing on-site setup time and delivering a fully integrated solution, SlotPro helped Apex Valves implement a workspace upgrade that made an immediate difference on the floor.

The Impact

The new assembly stations have become a valuable part of daily operations at Apex Valves. By integrating height adjustability, lighting, and power into each frame, SlotPro delivered a solution that supports both efficiency and operator wellbeing.

The consistent, ready-to-use design made it easy for the Apex team to implement the stations across their workspace without delay. With minimal setup required, the upgrade was completed smoothly and without disrupting production.