RMI

Creating A Custom Stair and platform Access Solution With SlotPro.

Background

RMI NZ Ltd is a New Zealand engineering and fabrication company based in Palmerston North. The business provides high-quality design, fabrication, and installation services across a wide range of industries, including manufacturing, infrastructure, and custom projects.

RMI has built a reputation for combining practical engineering expertise with precision workmanship. Their in-house team manages projects from concept through to completion, ensuring consistent quality and strong client collaboration throughout each stage.

Project Overview

Customer: RMI

SlotPro Products Used: 40 x 160 Slotpro 10 Slot Standard Extrusion, 40 x 120 SlotPro 8 Slot Standard Extrusion, 40 x 80 SlotPro 6 Slot Standard Extrusion, SPS 40 x 3 Aluminium Tube, SPS Side Base, SPS 40 x 150 Step Profile, SPS 40 x 100 Step Profile, SPS 135° Connector, SPS 45° L Connector, SPS 45° T Connector, SPS 45° Y Connector, 40/80 Angle Bracket, 4 Series Standard Connector 90°, 4 Series Roll in Slot Nut Spring M8, M14/M8 Hole Reducer Bolt, 4 Series Cover Cap 40 x 80, 90° Corner T-Joint Connector.

The Solution

RMI required a safe and adaptable stair and platform access system that could be replicated across multiple areas of their facility. Each unit needed to provide stable access around elevated equipment, meet workplace safety requirements, and remain easy to relocate or adjust if layouts were to change in the future.

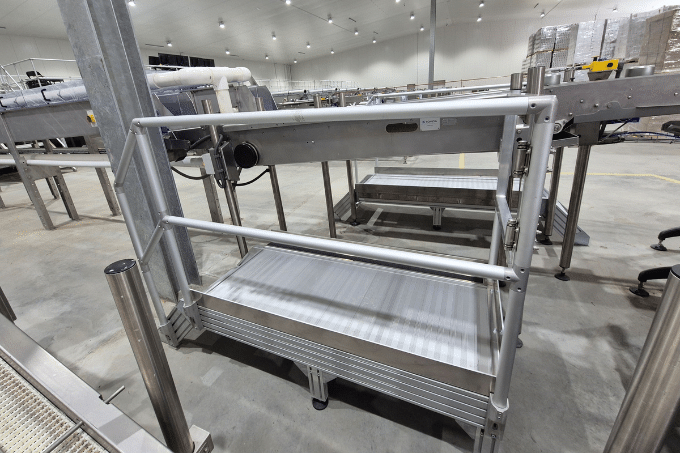

We worked alongside the project team to design and build five modular stair and platform units using a combination of 40 × 160, 40 × 120, and 40 × 80 SlotPro aluminium extrusions. The structures were supported with stair and platform components including step profiles, aluminium tube handrails, and side base systems for secure footing. Precision connectors such as 135°, 45° L, T, and Y joints were used to achieve clean angles, consistent alignment, and a professional finish.

All components were selected for strength, corrosion resistance, and compatibility within the SlotPro system. The stair and platform units were assembled on-site using standard connectors and fixings, allowing quick installation without welding or specialised tools. The result is a consistent, modular access solution that can be easily reconfigured or expanded to suit future requirements.

The Results

The installation of the stair and platform units have significantly improved safety and accessibility throughout RMI’s facility. Each platform provides stable, non-slip access with consistent step geometry, solid handrails, and clear entry points, helping staff move safely around elevated machinery and equipment.

The introduction of the stair and platform systems have removed the need for welded steel structures and eliminated common hazards such as uneven steps, sharp edges, and unstable ladders. The result is a modular, low-maintenance access system that enhances safety, streamlines movement within the workspace, and supports long-term adaptability as facility layouts evolve.

The Impact

The new stair and platform access systems have improved both safety and workflow efficiency within RMI’s facility. Staff now have secure, clearly defined access points for maintenance and inspection tasks, reducing downtime and minimising the risk of slips, trips, and falls.

The modular nature of SlotPro and stair and platform components, has also given RMI greater flexibility to adapt their workspace as needs evolve, without the cost or disruption of custom steel fabrication. This approach has streamlined site improvements, supported compliance with workplace safety standards, and delivered a professional, consistent appearance across the facility.