CUSTOM MACHINING SERVICES

Machining & Finishing Services.

At SlotPro, we provide a range of precision machining and finishing services to help you get the most from your aluminium profiles. From custom cut to length profiles and specialised milling for attachments to anodising, powder coating in your brand colours, and panels prepared to specification, our services are designed to suit your build requirements.

Each service supports faster assembly, improved accuracy, and a clean professional finish. By handling the machining and finishing in house, we help simplify your build process so you can focus on delivering your project with confidence.

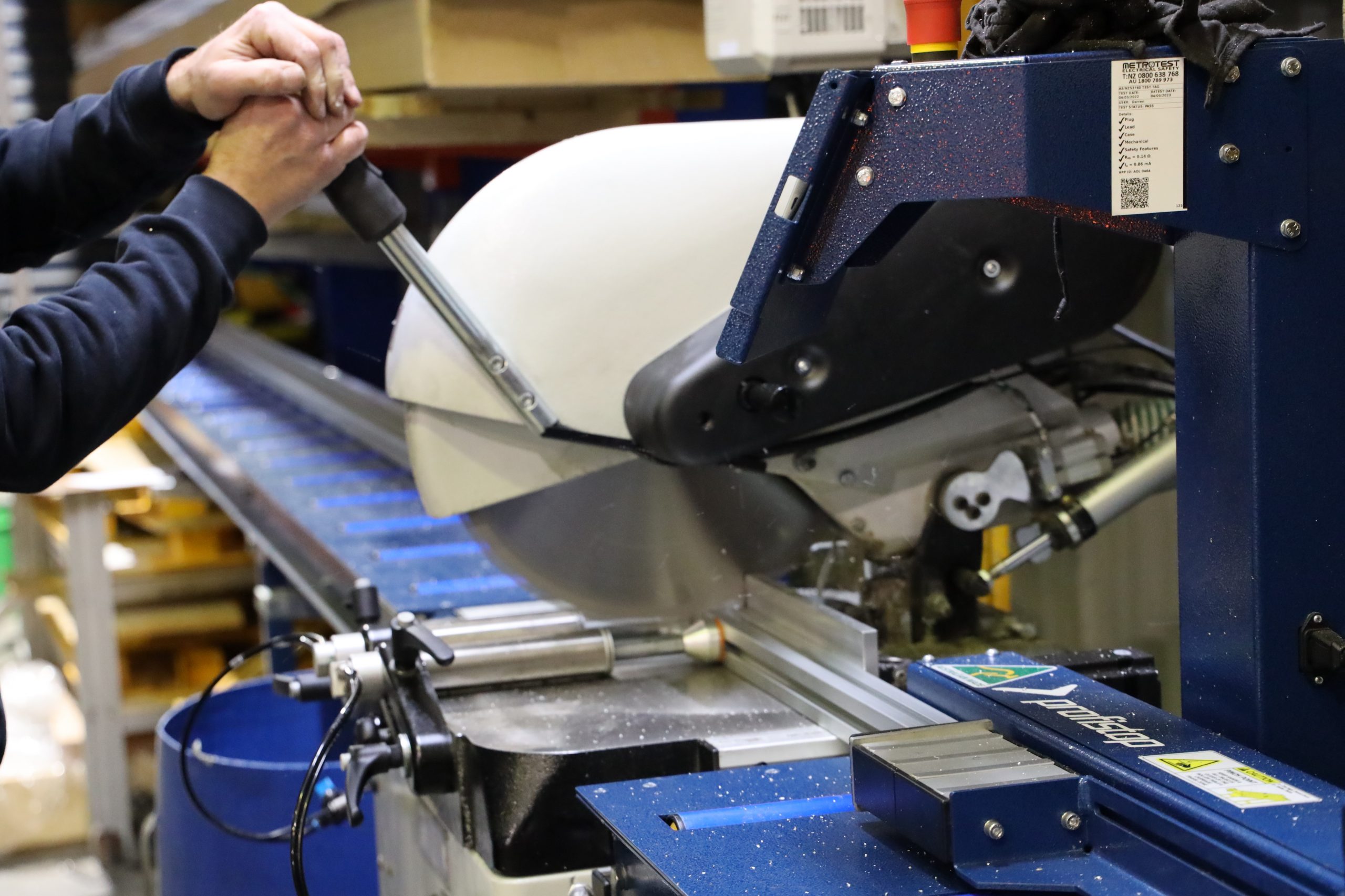

CUtting SERVICE

Custom Cut-To-Length Profiles.

SlotPro provides a precise cut to length service, allowing customers to order aluminium profiles in the exact sizes required for their project. Whether you are working on a one off build or a larger production job, any SlotPro profile can be cut to your specified length and supplied flat packed, ready for straightforward assembly.

Our cutting equipment is calibrated for consistent accuracy, delivering a cutting tolerance of less than ±0.5mm and a maximum cut length of 5800mm. Each profile is inspected after cutting, air blown, and wiped clean to remove swarf and machine residue, then carefully packaged to ensure it arrives in excellent condition.

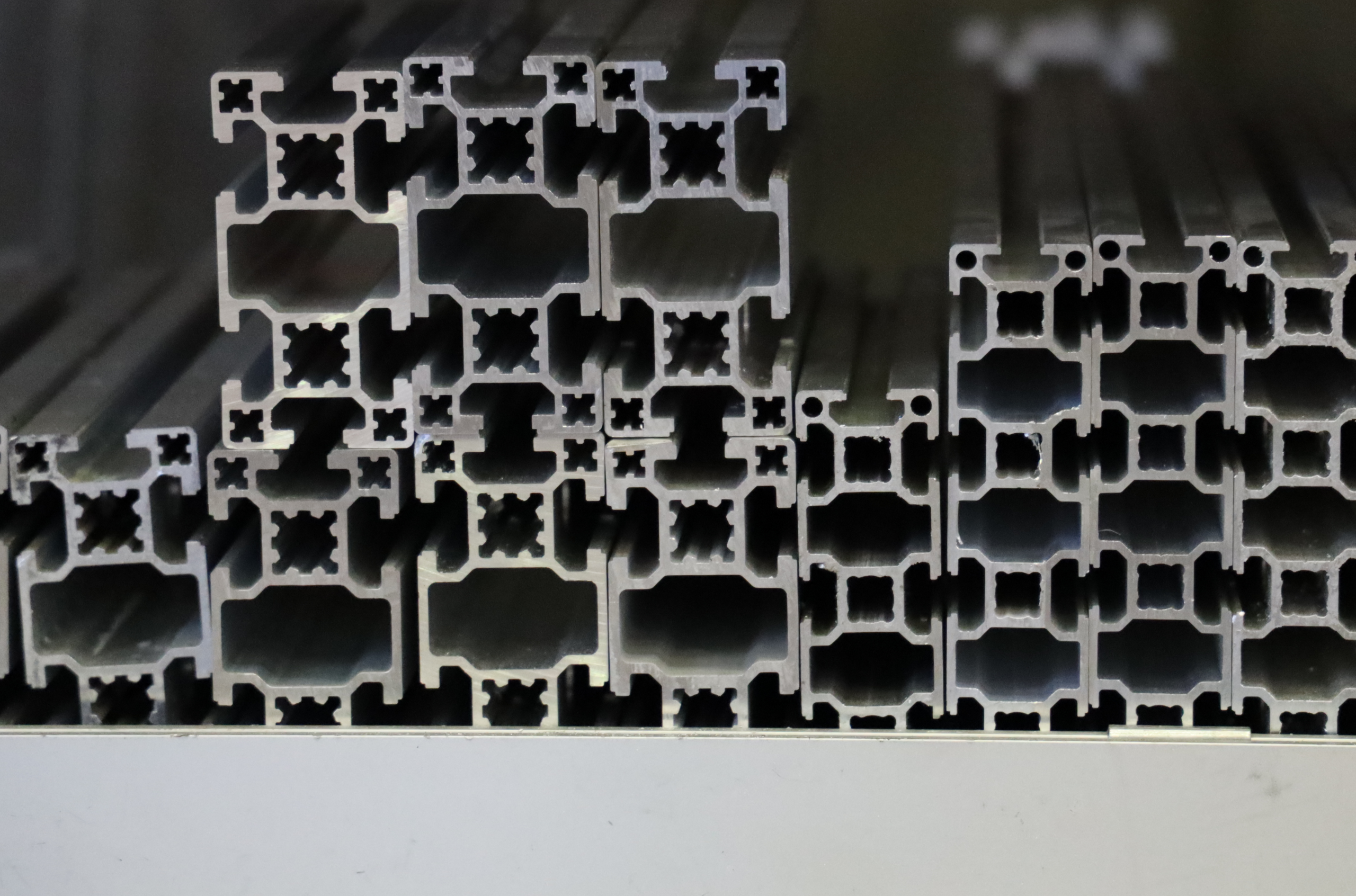

Milling SERVICE

Precision Milling for Custom Features.

Our milling service supports precise modifications to SlotPro profiles, allowing customised features to be built directly into the aluminium extrusion. Using CNC milling, we can accurately machine the T-slot itself or create specific details such as slots, holes, and recesses to suit your design.

This service is well suited to projects that require integrated connectors, brackets, or mounting hardware where standard components are not suitable. Each operation is completed with a strong focus on accuracy and finish, helping improve fit, simplify assembly, and support reliable performance in your final build.

Anodising FINISH

Durable Silver Anodised Profiles.

SlotPro profiles are finished with a high quality silver anodising process that improves durability and appearance. Anodising creates a protective oxide layer on the aluminium surface, increasing resistance to corrosion, wear, and weather exposure. This long lasting finish prevents oxidation and delivers a clean professional look, making it well suited to projects where performance and visual quality both matter. Suitable for indoor and outdoor use, anodised SlotPro profiles provide a strong and reliable solution designed for long term use.

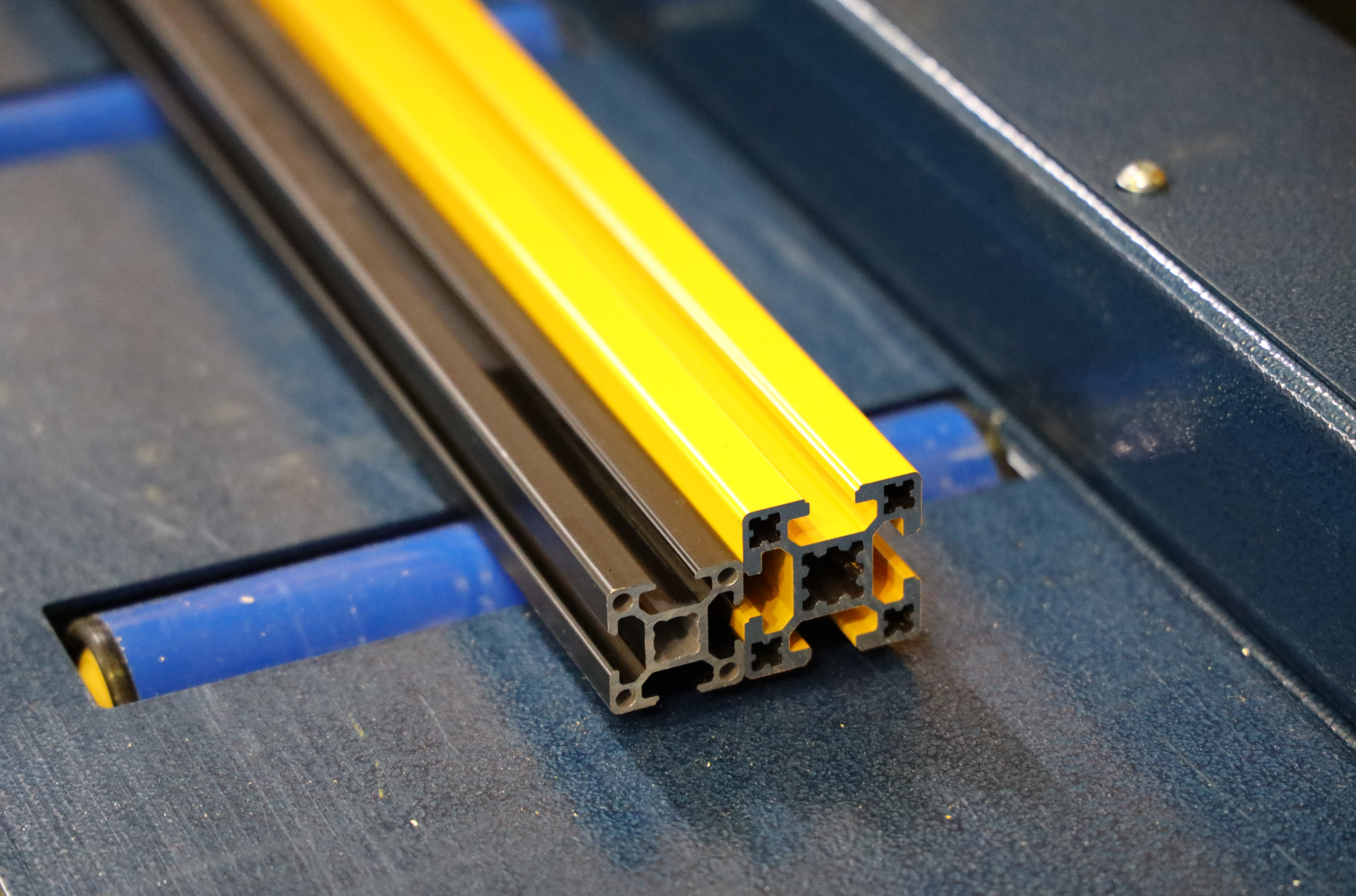

Powder COATING Option

Custom Powder Coated Finishes.

For projects that require a specific colour or strong visual impact, SlotPro offers custom powder coating for aluminium profiles. This durable finish enhances appearance while adding an extra layer of surface protection suited to industrial environments.

Common selections include safety yellow for the 1Guard Safety System and black for a clean modern finish, with a wide range of colours available to match your brand or design requirements. Contact our team for a powder coating quote tailored to your project and bring your build to life while maintaining the strength and quality of SlotPro aluminium.

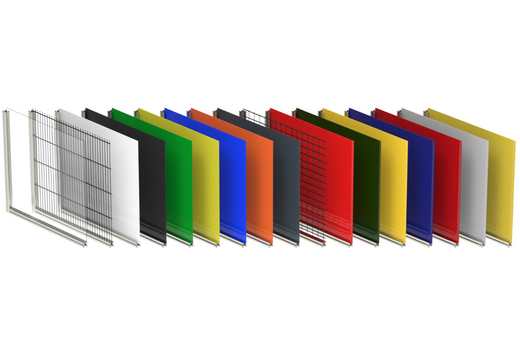

PANEL OPTIONS

Panels Cut And Prepared For Your Project.

SlotPro can supply panels to complete your project, whether for structural support, visual design, or safety applications. We offer a wide range of plastic, polyethylene, and wire mesh panels in multiple colours and thickness options, suitable for both interior and exterior environments. Each panel is prepared to your specifications and supplied ready to assemble within your SlotPro system.

Our most popular panel materials include:

ACM (Aluminium Composite Material)

ACM panels consist of a thermoplastic polyethylene core bonded between two flat aluminium sheets, creating a lightweight, strong, and smooth surface. They are ideal for applications such as exterior signage, shopfitting, cabinetry, trade displays, partitions, and ceilings.

Key Features:

- Excellent surface flatness

- Weather and corrosion resistance

- Easy maintenance

- Lightweight fabrication.

Acrylic (Continuous Cast Sheet)

This crystal-clear sheet is made by curing polymerised acrylic between polished steel plates for high optical clarity and stability. Commonly used in picture frames, light diffusers, boat windscreens, skylights, aquariums, and safety guards.

Key Features:

- Superior weather resistance

- Consistent thickness

- Strong impact resistance (better than glass)

- High transparency.

Polycarbonate

A highly durable, transparent thermoplastic with UV resistance, flame retardancy, and a long service life. Often used for overhead glazing, security barriers, skylights, machine guards, menu boards, and signage.

Key Features:

- Exceptional impact strength

- Crystal-clear clarity

- Lightweight

- Outstanding resistance to weather and ageing

If you have specific requirements or need help selecting the right panel, get in touch for a tailored quote. Our team can assist with choosing the best option to support your design and application requirements.